ERW Pipes

ERW (Electrical Resistance Welding) pipes are produced by cold-forming steel coil into a cylindrical shape. In the beginning, edges were heated with low-frequency alternating current.

ERW pipes have several applications, including fencing, line pipe, and scaffolding, among others. There are many diameters, wall thicknesses, finishes, and grades available for ERW steel pipes. Water pipelines, Agriculture & Irrigation (Water mains, industrial water pipe lines, plant piping, deep tube-wells & casing pipes, sewage piping), Gas pipelines, LPG and other non-toxic gas lines are the most common applications.

LSAW Pipes

LSAW Pipe (Longitudinal Submerged Arc-Welded Pipe) is also referred to as SAWL pipe. As the raw material, the steel plate is shaped by a molding machine, and then double-sided submerged arc welding is performed. The LSAW steel pipe will acquire superior ductility, weld toughness, homogeneity, plasticity, and sealing using this method.

LSAW pipe diameter range is typically between 16 inches and 60 inches, or 406 millimeters and 1500 millimeters. Excellent resistance to corrosion at low temperatures and at high pressures.

SSAW Pipes

SSAW Pipe (Spiral Submerged Arc-Welding Pipe), also known as HSAW Pipe (Helical Submerged Arc-Welding Pipe), has a helix-shaped welding line. LSAW pipe utilizes the same welding method as Submerged Arc-Welding. LSAW pipe is longitudinally welded, whereas SSAW pipe is spirally welded. Rolling the steel strip to create an angle between the rolling direction and the direction of the pipe's center, followed by shaping and welding to create a spiral seam.

The diameter range for SSAW pipes is 20 inches to 100 inches, or 406 mm to 2540 mm.

The advantage is that multiple diameters of SSAW pipes may be made from the same size of steel strip, there is a wide range of applications for steel strip as a raw material, and welding seams should avoid primary stresses and have excellent stress-bearing capabilities.

The disadvantage is poor physical dimensions; the length of the welding seam is more than the length of the pipe; and it is possible to produce defects such as cracks, air holes, cinder inclusion, partial welding, and welding force in pulling state.

In petroleum design specifications, the SSAW pipe / HSAW pipe could only be used in class 3 and class 4 areas for oil and gas pipeline systems. Construction, water transportation and sewage treatment, thermal industries, structures, etc.

Seamless Pipes

Steel in sheet or bar form is shaped into solid spherical "billets" that are then heated and cast over a form such as a penetrating rod to produce a hollow tube or shell. These pipes are noted for their superior capacity to bear pressure compared to conventional pipe manufacturing procedures, as well as their speed and cost-effectiveness. Typically, gas lines and liquid-carrying pipes are constructed with seamless pipes.

Because seamless pipes can sustain high pressures, they are commonly utilized in high-pressure applications such as refineries, hydraulic cylinders, the hydrocarbon industry, and Oil & Gas infrastructure.

In contrast to other types of piping, seamless pipes do not require welding or connections. Instead, they are made from solid round billets, which contributes to their strength and other qualities, such as corrosion resistance.

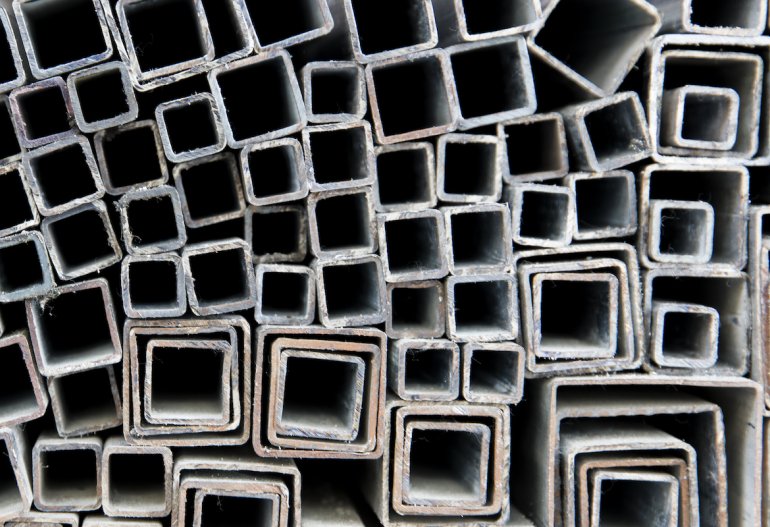

Steel Hollow Sections

Internally hollow structural sections are metal profiles with a hollow cross section. They are some of the most adaptable, dependable, and cost-effective types of steel that may be utilized in a variety of mechanical and building applications. Interestingly, a significant proportion of modern structural foundations are comprised of hollow portions.

Steel hollow sections are available in round, rectangular, and square configurations. Each form of hollow section has distinct characteristics that make it suitable for particular applications.